Innovative Solutions for Thermal Applications

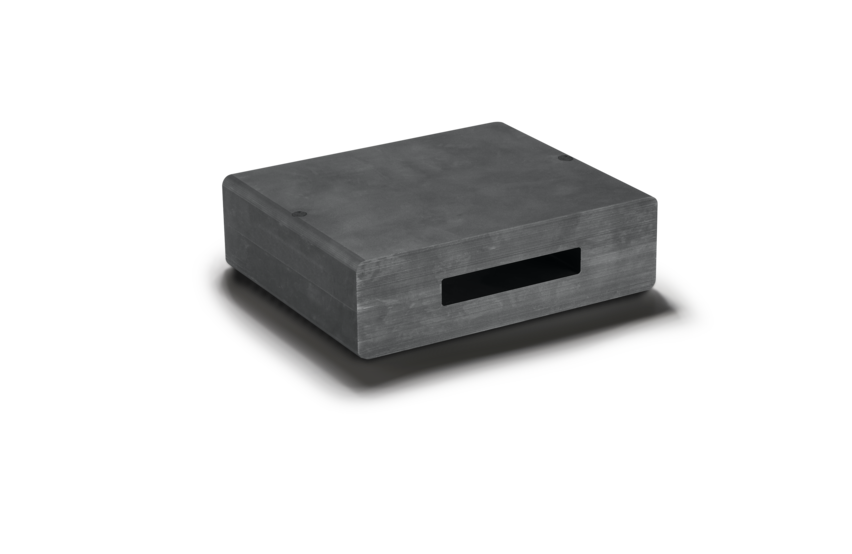

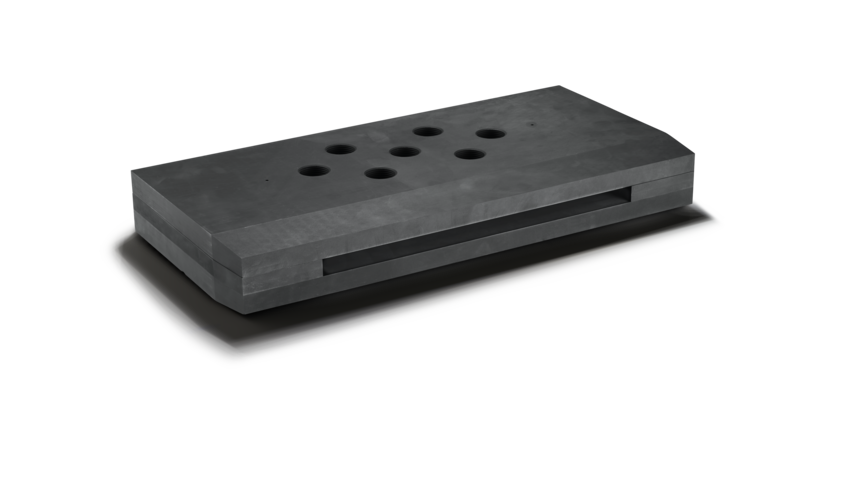

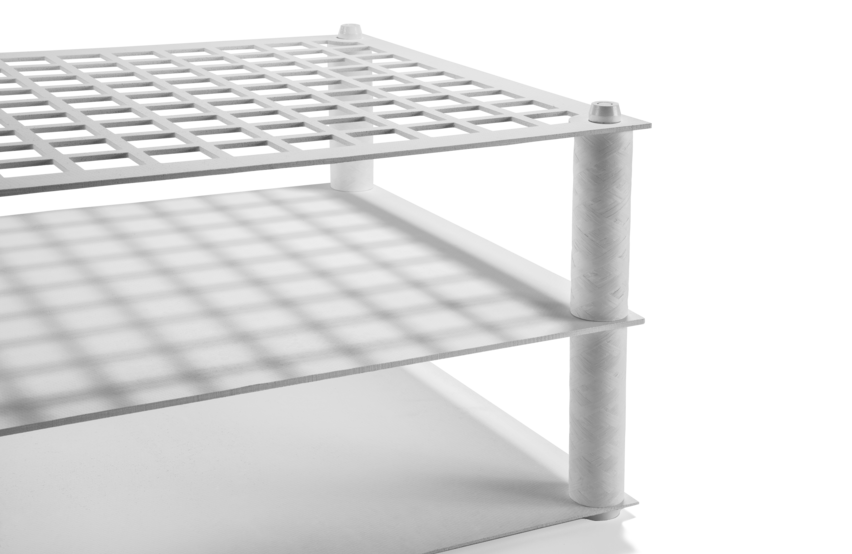

Graphite Continuous Casting Mould

In continuous casting, molten metal is continuously fed into the mold, where it solidifies and can thus be withdrawn. Graphite has proven to be a superior material for the mold, as it has no negative influence on the composition of the finished product. In addition, graphite is characterized by the fact that the molten metal does not wet the graphite surface. Thanks to our many years of experience and extensive materials expertise, we are able to optimally design the graphite materials and their processing for our molds to suit the application required by the customer. In doing so, we have a wide variety of materials and finishing techniques at our disposal.

Take advantage of these benefits:

- Low wettability of the mold surface

- Good chemical and thermal resistance

- Good thermal conductivity

- Excellent thermal shock resistance

- Low thermal expansion

- Good lubricating and sliding properties

- Non-ferrous metal and its alloys

Heat treatment with high-level know-how

New solutions for your applications

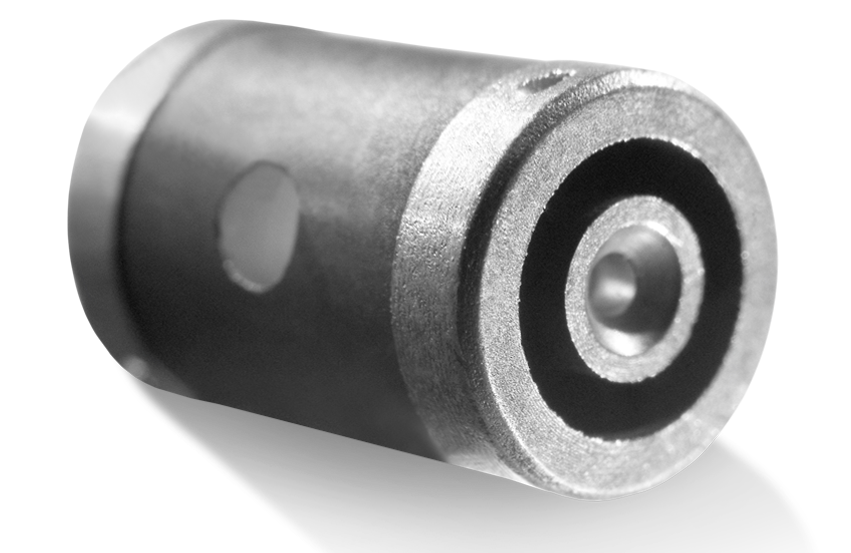

The solution for oil quenching

Standard parts list in the field of high temperature applications

Schunk Industry: Leading the Way in Glass Handling